They're fine on a washing machine or a toaster but they shouldn't be used on fucking motorcycles!

Hex nuts and bolts are great. if you have an M8 bolt the widest diameter of the threaded part is 8mm. The hex head is generally 13mm across the flats and its about 15mm across the corners. The salient point of this is that when you apply force to the head of the bolt with a wrench, neither the tool nor the head of the bolt have a particularly stressful time because they're big and they have a mechanical advantage over the 8mm threaded part of the bolt. And so long as you use a wrench of reasonable quality and the correct size, everybody is happy.

Socket (Allen Key) bolts are great too. Your M8 Allen bolt uses a 6mm across the flats Allen key that's a little under 8mm across the corners. There is a slight mechanical disadvantage but both the head and the tool are pretty robust so provided you use a reasonably good quality tool, generally there's no problem. In addition to being reliable, Socket heads look really nice and can be used in areas where a hex head won't fit. Also, they can be sunk flush to the surface and this looks even nicer. I fucking love Allen bolts - especially stainless steel Allen bolts. Each and every one is little sparkly, magical unicorn-poop-diamond to me.

But fucking Torx!! I fucking hate Torx! A Torx tool is essentially similar to an Allen key except that a fair proportion of material has been removed from the tip of the tool making it substantially weaker. The bolt head has a corresponding amount of metal added to it which perversely makes it weaker too! This might seem counter intuitive but what happens is that all the force acts on the weakest part of the tool and the weakest part of the head and they just break each other to bits. It's a fucking stupid idea for high torque applications so if you happen to know the person who first thought of fitting one to a motorcycle, I'd appreciate if you punched him on the nose. Thanks.

So why all the ranting?

Well, I'm still working on my fucking Buell. It normally takes me between a half a day and a day to strip a motorcycle (even old, rusty abused motorcycles from the '70s), but every single bolt on this fucking bike is seized. Today's all-day twenty-minute job was stripping the hardware off the wheels so I can send them for powder coating.

I can't bring myself to write about the details, but everything was difficult and everything took a lot of time and a series of escalating techniques. I've picked up a couple of small injuries and broken several tools not to mention some small collateral damage to stuff in the workshop.

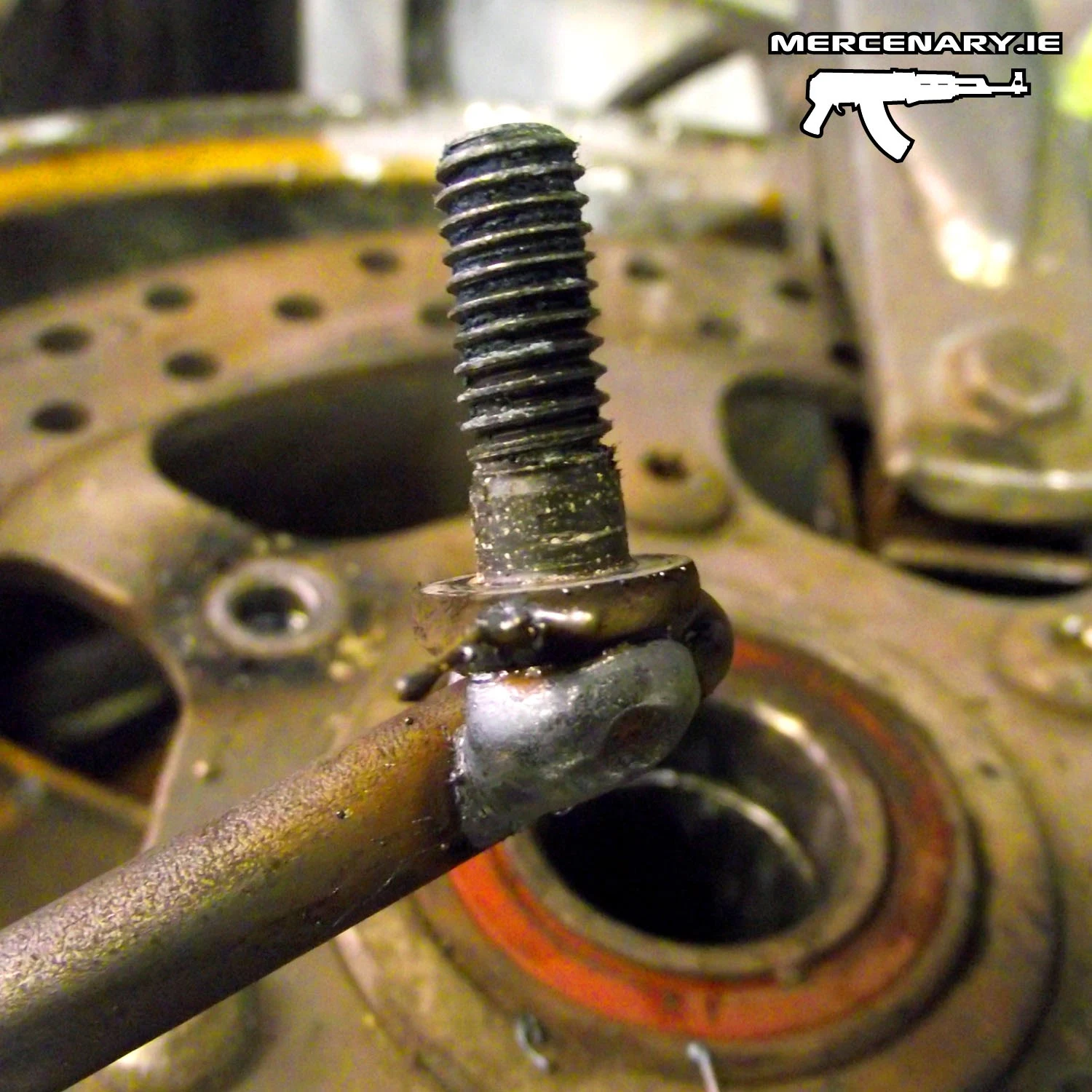

The most annoying part was removing the Loc-Tited Torx bolts holding the brake rotors. In the end, I welded on lengths of 8mm steel rod to the heads of the bolts in lieu of breaking more tools. The combination of heat and leverage worked a treat.

Anyway, I prevailed and I'm off to the powder-coaters in the morning.

|

| That's a lot of Loc-Tite. A brake rotor is a fucking service item - it should be removable without all this trauma! |

|

| This is a really useful technique. Obviously the bolts aren't in any condition to be reused, but everything else survived. The post-battle StarWars aesthetic will polish out with Scotchbrite. |

|

| Motherfuckers. |

#Buell #Torx #MotorcycleWorkshop #Mercenary #MercenaryGarage

No comments:

Post a Comment

Leave a Comment...